Caterpillar C9 Diesel Engines

Original price was: $11,588.00.$11,255.00Current price is: $11,255.00.

Find a high-performance Basic Long Block. This Caterpillar C9 Diesel Engine series, featuring advanced ACERT technology and electronic controls, delivers formidable power for a wide range of heavy-duty and industrial applications. Final price depends on your specific setup.

Description

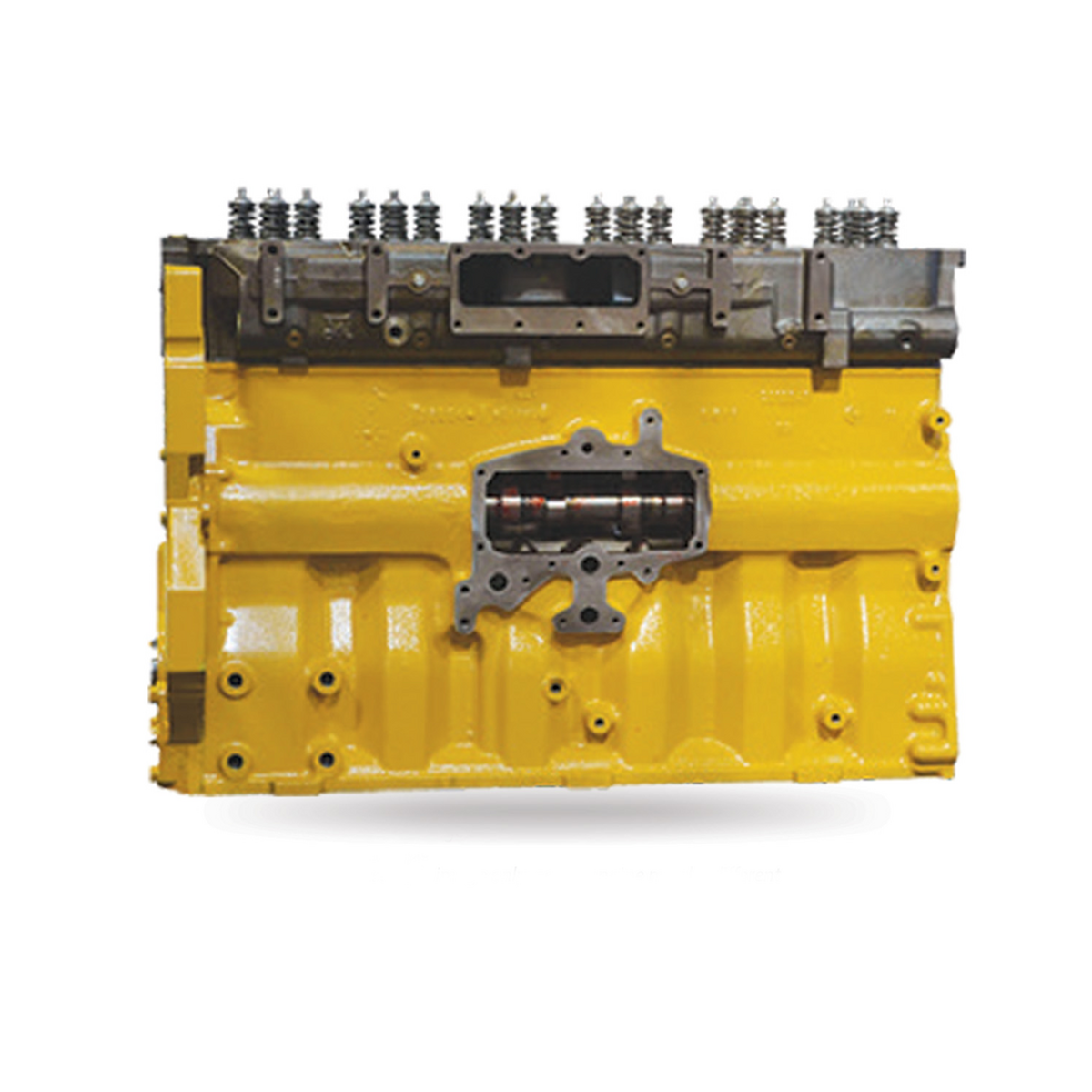

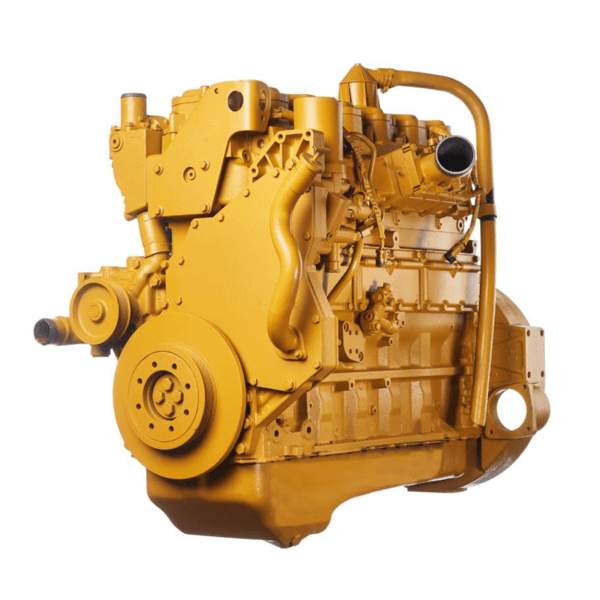

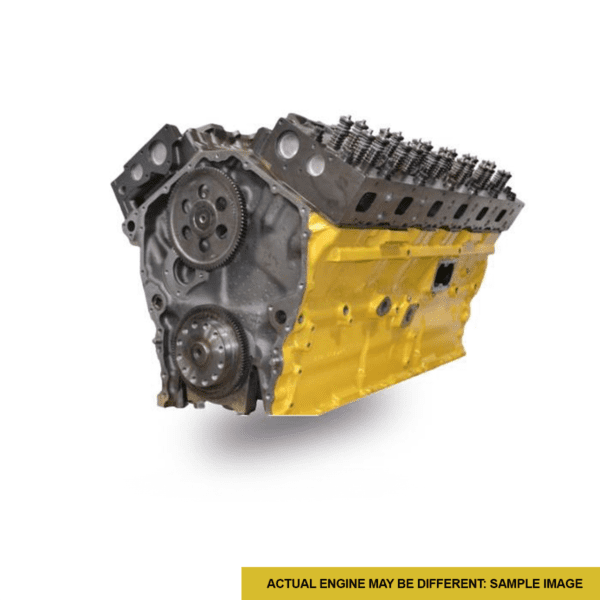

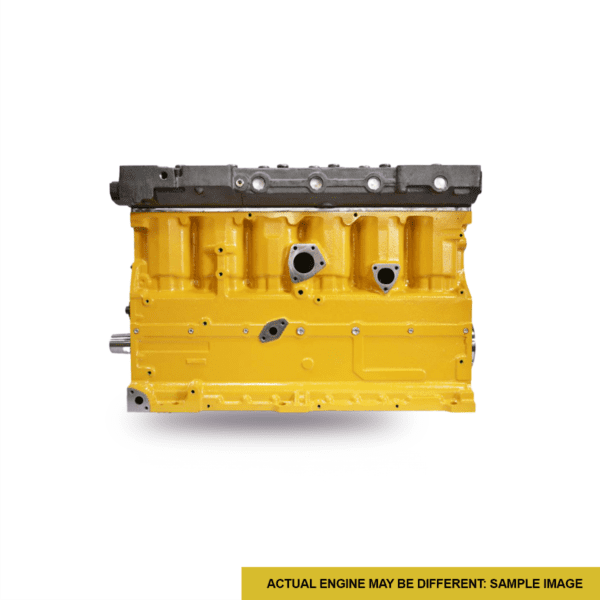

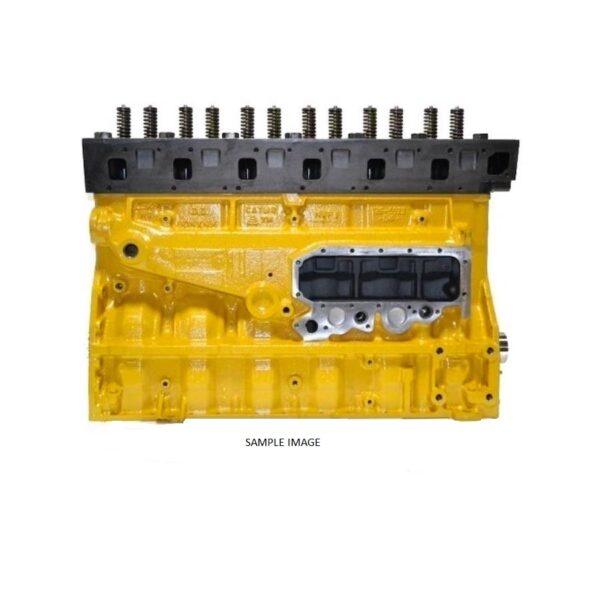

Power your heavy-duty equipment, industrial machinery, or marine vessels with a high-quality Caterpillar C9 Diesel Engine Basic Long Block. These advanced inline-6 diesel engines stand out. They feature electronic control, impressive horsepower, and ACERT™ Technology. This ensures efficiency and reliability in demanding environments. Please note, the final price depends on your specific setup and any required components.

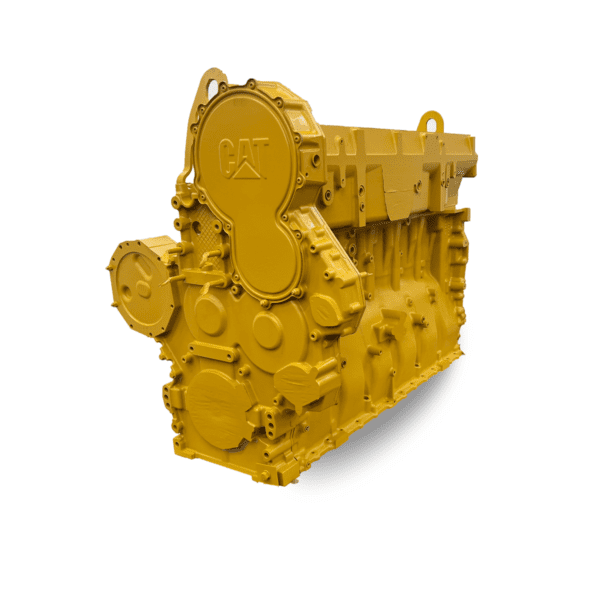

The Caterpillar C9 Diesel Engine family includes variants like the C9 ACERT and C9.3 ACERT/C9.3B. It showcases Caterpillar’s commitment to advanced engine technology. Displacements typically range from 8.8L to 9.3L. These engines use sophisticated electronic controls, such as the ADEM™ A4 ECM. Often, they also incorporate the HEUI™ (Hydraulically Actuated Electronic Unit Injection) fuel system. Furthermore, ACERT™ Technology enhances performance. It optimizes air management, combustion, and aftertreatment. This results in cleaner emissions, improved fuel economy, and strong power delivery across a broad operating range.

Key Features and Specifications

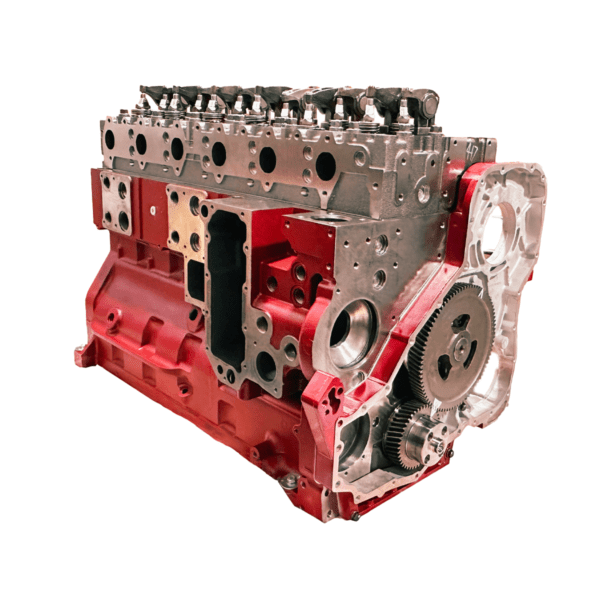

- Engine Configuration: These are robust inline-6, 4-stroke cycle diesel engines. They feature durable cast-iron blocks and cylinder heads. They are built to withstand continuous heavy loads.

- Displacement Options: Common displacements for the Caterpillar C9 Diesel Engines include 8.8 Liters (537 cubic inches) and 9.3 Liters (567.5 cubic inches). These options provide versatile power outputs.

- ACERT™ Technology: This innovative technology optimizes engine performance. It precisely manages air, combustion, and electronics. This leads to better fuel efficiency and reduced emissions.

- Electronic Control (ECM): Equipped with advanced Electronic Control Modules, C9 engines offer precise control over fuel injection and engine timing. This ensures responsive and efficient power.

- High Horsepower & Torque: The C9 family typically delivers horsepower from 275 HP to 456 HP. They also provide substantial torque outputs (e.g., up to 1540 lb-ft). Thus, they are suitable for high-demand applications.

- Fuel System: Many C9 models feature the HEUI™ fuel system. This system provides electronically controlled, high-pressure fuel injection. It ensures optimal performance and efficiency.

Common Engine Applications

The Caterpillar C9 Diesel Engine’s versatile power and advanced features make it ideal for a wide array of demanding applications. For example, you’ll commonly find these engines in:

- Construction Equipment: They power large excavators, loaders, dozers, compactors, cranes, and other heavy construction machinery.

- Agricultural Machinery: These engines are utilized in large tractors, combines, and irrigation pumps.

- Industrial Power Units: They drive generator sets, compressors, pumps, and other stationary or mobile industrial machinery.

- Marine Propulsion: Furthermore, they serve as reliable main propulsion or auxiliary power in various commercial and pleasure craft.

- Mining & Forestry: They provide robust power for mining equipment, chippers, grinders, and forestry machinery.

Our Caterpillar C9 Diesel Engines Basic Long Blocks are meticulously prepared to high standards. This ensures a reliable and long-lasting engine solution. It is ready to deliver peak performance for your valuable equipment.

Get A Quote On This Engine

Questions?

Our experts are ready to help call us at (888) 655-4615

Additional information

| Basic Long Block | Block, Camshaft, Crankshaft, Cylinder Head, Front Housing, Lifters, Pistons, Rods |

|---|

Nationwide Warranty

Long Block configurations: 1 year/unlimited mileage.

Off-Road All configurations: 1 year/2,000 hours.

Motorhome/RV Applications: 1 year parts and labor only.

Some restrictions apply; see limited warranty details or call for more information.

- All engines are assembled in the USA.

- Replaces 100% of rings, bearings, bushings, gaskets, and seals.

- Matched OEM requirements for piston type depending upon HP and application.

- All heads get new valves and are vacuum tested to ensure the quality of the valve job. All heads are pressure tested and upgraded to the latest style valve seal.

- Cylinder head seats replaced 100% new.

- Camshaft is checked for size, reground, if necessary, and micropolished to OEM specifications.

- All connecting rods are demagnetized.

- Core plugs are 100% stainless steel to avoid corrosion.

- Blocks, heads and crankshafts are 100% magnaflux tested to avoid cracked components.

- Connecting rods have new bushings installed and both large and small end are remachined to OEM specifications.

Crankshaft is checked for size, reground, if necessary, and micropolished to OEM specifications.

ENGINE TESTING

Every engine is machined using state-of-the-art equipment and assembled using precise and repeatable methods. All engine production follows documented lean manufacturing processes and principles to create consistent quality and dependable outcomes.

All Short Block, Long Block, and Long Block Premium are 100% Sim tested before shipment.

Complete Drop-In engines are 100% dyno tested before shipment. Computer controls ensure that each engine dyno test is conducted under standard, repeatable settings. Every engine is run through a warm-up cycle; three separate cruise segments simulating light, medium, and heavy throttle conditions; maximum torque and horsepower tests; both high and low idle tests; and a black light leak detection test with dyed oil, coolant, and fuel.

we’ve been delivering remanufactured engines for skid steer loaders for over 30 years—longer than any competitor in the industry. Our veteran machinists, many with decades of experience, follow engine-specific rebuild procedures to ensure consistent quality with every unit.

Each engine is carefully rebuilt to meet or exceed OEM specifications, using top-tier components and proven techniques. This is more than just a repair—it’s a full remanufacturing process designed to restore the engine to like-new condition.

Before shipping, every complete skid steer engine is dyno-tested for performance and reliability, so you can install with confidence.