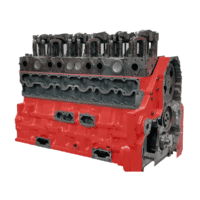

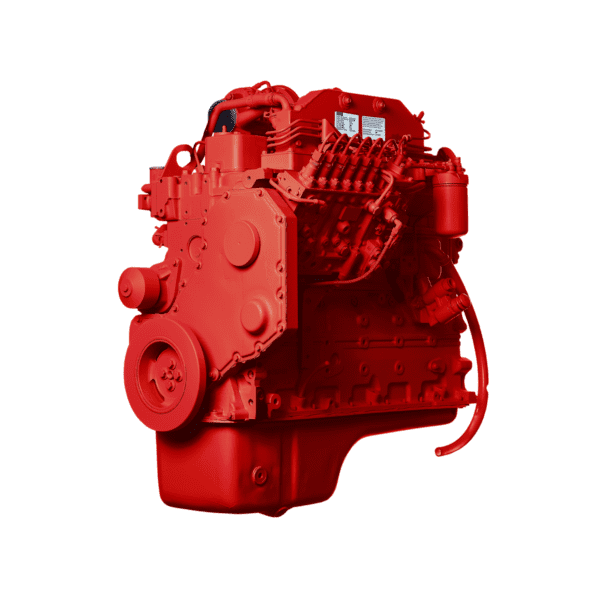

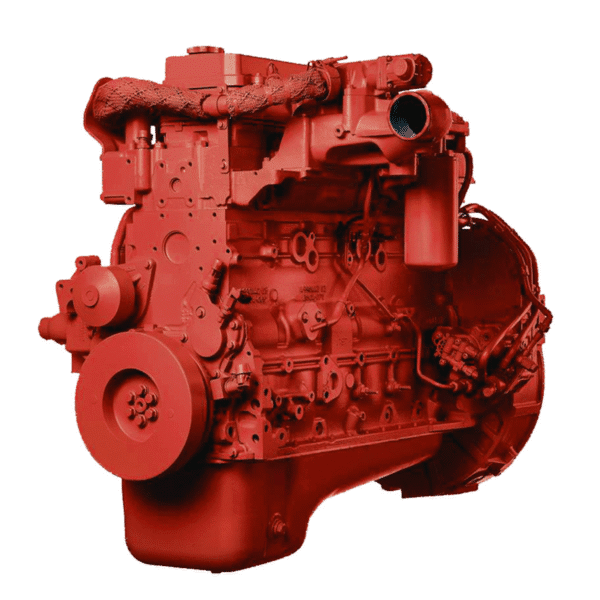

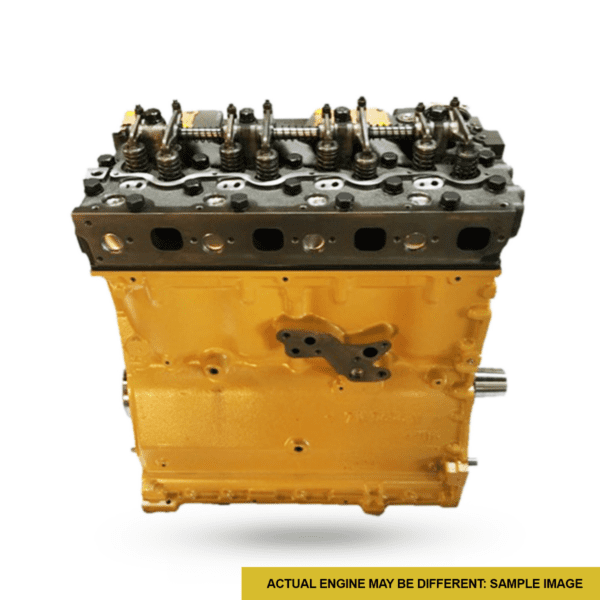

Cummins ISM 10.8 L inline‑6 Diesel Engines

Original price was: $14,800.00.$14,588.00Current price is: $14,588.00.

Find reliable Cummins ISM 10.8L Inline-6 Diesel Engines in Basic Long Block configuration. Ideal for vocational trucks, transit buses, RVs, and industrial equipment, these engines are proudly assembled in the USA.

Description

Power your demanding applications with our high-quality Cummins ISM 10.8L Inline-6 Diesel Engines. We offer these robust and reliable engines in a Basic Long Block configuration, providing an excellent foundation for your engine replacement or rebuild project. Price is subject to specific engine specifications and intended use.

The Cummins ISM is a highly respected engine known for its durability, efficiency, and proven performance across a variety of heavy-duty uses. It is ideally suited for:

- Vocational trucks

- Transit buses

- RVs (Recreational Vehicles)

- Various industrial equipment

Every engine we supply is meticulously assembled in the USA, ensuring the highest standards of quality, precision, and long-term reliability.

Get A Quote On This Engine

Questions?

Our experts are ready to help call us at (888) 655-4615

Additional information

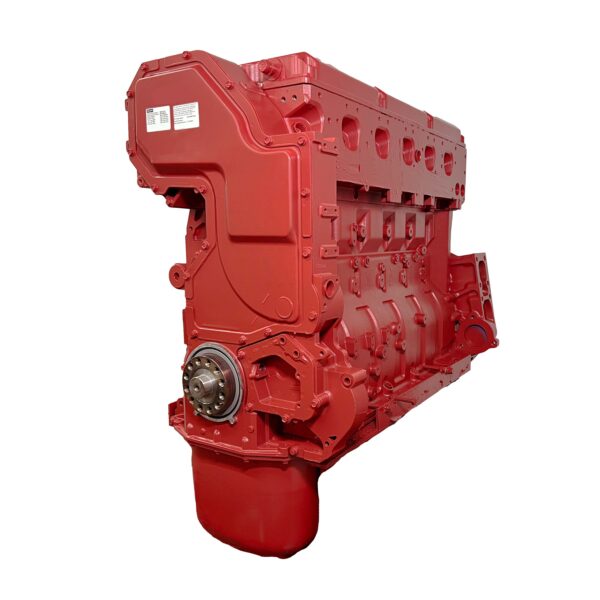

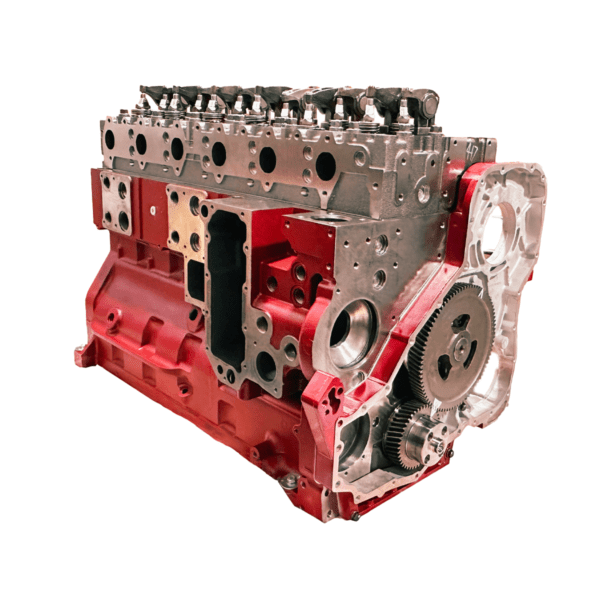

| Basic Long Block | Block, Camshaft, Camshaft Followers (new pins/rollers), Complete Gasket Set, Crankshaft, Front Housing, Gasket Set, Head, Pistons, Rocker Assembly, Rods |

|---|

Nationwide Warranty

Long Block configurations: 1 year/unlimited mileage.

Off-Road All configurations: 1 year/2,000 hours.

Some restrictions apply; see limited warranty details or call for more information.

- All engines are assembled in the USA.

- Replaces 100% of rings, bearings, bushings, gaskets, and seals.

- Matched OEM requirements for piston type depending upon HP and application.

- All heads get new valves and are vacuum tested to ensure the quality of the valve job. All heads are pressure tested and upgraded to the latest style valve seal.

- Cylinder head seats replaced 100% new.

- Camshaft is checked for size, reground, if necessary, and micropolished to OEM specifications.

- All connecting rods are demagnetized.

- Core plugs are 100% stainless steel to avoid corrosion.

- Blocks, heads and crankshafts are 100% magnaflux tested to avoid cracked components.

- Connecting rods have new bushings installed and both large and small end are remachined to OEM specifications.

Crankshaft is checked for size, reground, if necessary, and micropolished to OEM specifications.

ENGINE TESTING

Every engine is machined using state-of-the-art equipment and assembled using precise and repeatable methods. All engine production follows documented lean manufacturing processes and principles to create consistent quality and dependable outcomes.

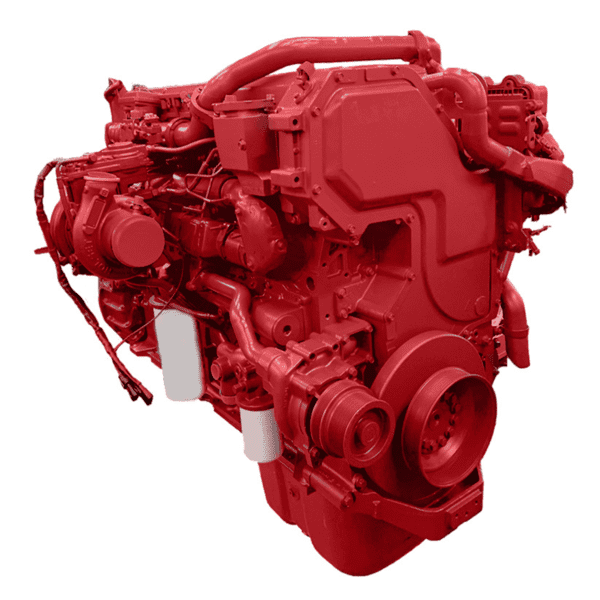

All Short Block, Long Block, and Long Block Premium are 100% Sim tested before shipment.

Complete Drop-In engines are 100% dyno tested before shipment. Computer controls ensure that each engine dyno test is conducted under standard, repeatable settings. Every engine is run through a warm-up cycle; three separate cruise segments simulating light, medium, and heavy throttle conditions; maximum torque and horsepower tests; both high and low idle tests; and a black light leak detection test with dyed oil, coolant, and fuel.

we’ve been delivering remanufactured engines for skid steer loaders for over 30 years—longer than any competitor in the industry. Our veteran machinists, many with decades of experience, follow engine-specific rebuild procedures to ensure consistent quality with every unit.

Each engine is carefully rebuilt to meet or exceed OEM specifications, using top-tier components and proven techniques. This is more than just a repair—it’s a full remanufacturing process designed to restore the engine to like-new condition.

Before shipping, every complete skid steer engine is dyno-tested for performance and reliability, so you can install with confidence.