Description

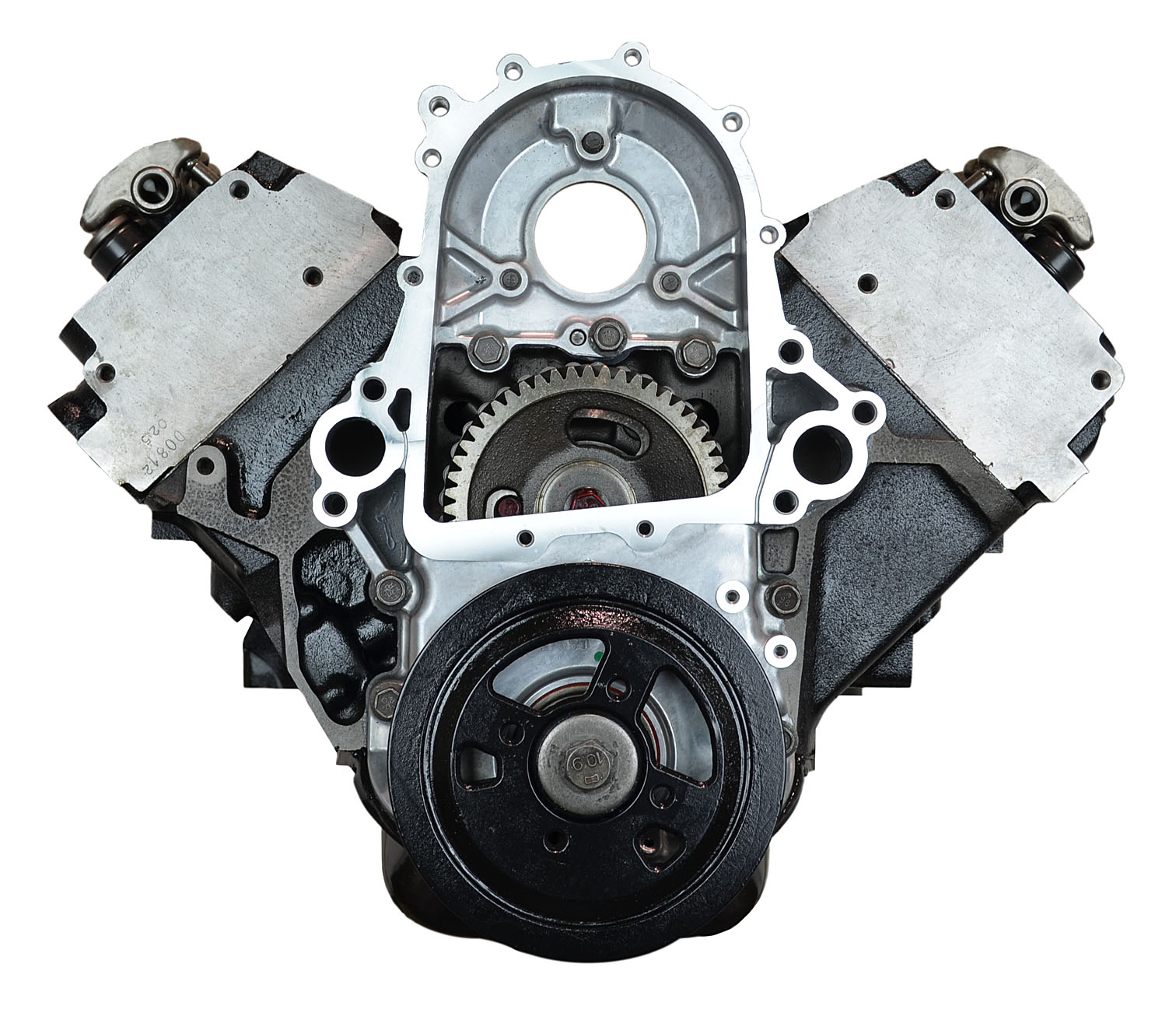

Chevrolet / GMC 6.5L Diesel Engine (1996–2002) – Updated Block Version

Upgrade your diesel power with this remanufactured GM 6.5L turbo diesel engine, precision-built to OEM specifications and featuring the January 2009 updated block for improved strength, oil flow, and reliability.

This direct-fit replacement engine is designed for Chevrolet and GMC trucks, SUVs, and vans from 1996 through 2002, including:

Silverado / Sierra 1500–3500, Suburban, Yukon, Tahoe, and Express / Savana vans.

Key Features:

-

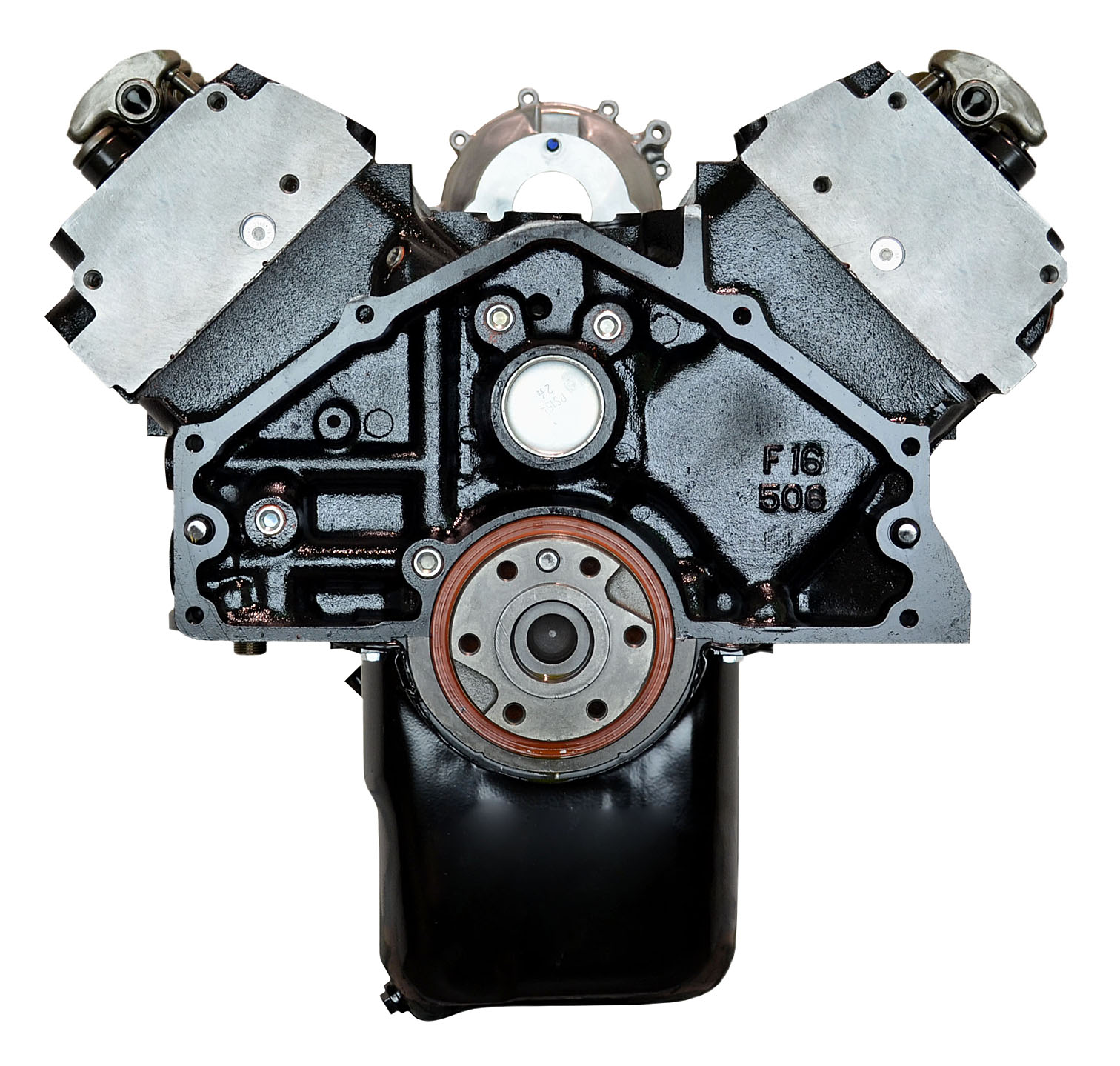

Updated 2009 Block Design: Stronger casting reduces stress cracking and improves oil circulation.

-

Big Oil Return Hole: Enhances lubrication and cooling for longer engine life and smoother performance.

-

45° Intake Mount Holes: Allows for improved air intake positioning and easier turbo alignment.

-

Remanufactured to OEM Standards: Fully rebuilt with premium components, precision machining, and balanced rotating assembly.

-

Plug-and-Play Installation: Direct drop-in replacement with no major modifications required.

-

Compatible with VIN Code “F” and block casting #506 applications.

Fitment Applications (1996–2002):

- Not compatible with motorhome installations ( Warranty is void if installed in motorhome applications).

-

Chevrolet: Silverado, Suburban, Tahoe, Express Van

-

GMC: Sierra, Yukon, Yukon XL, Savana Van

(Verify VIN and block casting number before purchase.)

Why Choose This 6.5L Diesel Engine:

This remanufactured GM 6.5L diesel offers OEM reliability with modern upgrades, making it an ideal replacement for aging factory engines. It delivers better oil management, reduced blow-by, and long-term dependability in towing, fleet, and work applications.

Nationwide Warranty

Gas Engines Warranty Comparison

| Warranty Type | Duration / Mileage | Parts & Labor | No-Fault (NF) Coverage |

|---|---|---|---|

| ⭐ Gold Warranty (Recommended) | 4 Years / Unlimited Miles | ✅ Included | ✅ Included |

| Silver Warranty | 3 Years / 100,000 Miles | ✅ Included | ✅ Included |

| Engine Warranty | 2 Years / 24,000 Miles | ✅ Included | — |

| Manufacturer Warranty | Varies by OEM (e.g., Ford, GM, others) | ✅ Included | — |

Important Notes

-

Warranty coverage may vary depending on the specific engine.

-

Some engines carry different warranty terms — please contact us for exact coverage details.

-

Certain engines are backed by the manufacturer’s original warranty (such as Ford, GM, and more).

-

Some restrictions apply; see limited warranty details or call for more information.

- All engines are assembled in the USA.

- Replaces 100% of rings, bearings, bushings, gaskets, and seals.

- Matched OEM requirements for piston type depending upon HP and application.

- All heads get new valves and are vacuum tested to ensure the quality of the valve job. All heads are pressure tested and upgraded to the latest style valve seal.

- Cylinder head seats replaced 100% new.

- Camshaft is checked for size, reground, if necessary, and micropolished to OEM specifications.

- All connecting rods are demagnetized.

- Core plugs are 100% stainless steel to avoid corrosion.

- Blocks, heads and crankshafts are 100% magnaflux tested to avoid cracked components.

- Connecting rods have new bushings installed and both large and small end are remachined to OEM specifications.

Crankshaft is checked for size, reground, if necessary, and micropolished to OEM specifications.

ENGINE TESTING

Every engine is machined using state-of-the-art equipment and assembled using precise and repeatable methods. All engine production follows documented lean manufacturing processes and principles to create consistent quality and dependable outcomes.

All Short Block, Long Block, and Long Block Premium are 100% Sim tested before shipment.

Complete Drop-In engines are 100% dyno tested before shipment. Computer controls ensure that each engine dyno test is conducted under standard, repeatable settings. Every engine is run through a warm-up cycle; three separate cruise segments simulating light, medium, and heavy throttle conditions; maximum torque and horsepower tests; both high and low idle tests; and a black light leak detection test with dyed oil, coolant, and fuel.

we’ve been delivering remanufactured engines for skid steer loaders for over 30 years—longer than any competitor in the industry. Our veteran machinists, many with decades of experience, follow engine-specific rebuild procedures to ensure consistent quality with every unit.

Each engine is carefully rebuilt to meet or exceed OEM specifications, using top-tier components and proven techniques. This is more than just a repair—it’s a full remanufacturing process designed to restore the engine to like-new condition.

Before shipping, every complete skid steer engine is dyno-tested for performance and reliability, so you can install with confidence.